SiC heating elements designed for the most challenging applications where conventional silicon carbide elements are unsuitable. STA Globar HD SiC heating elements feature hot zones of high density, low permeability, reaction-bonded silicon carbide, which is highly resistant to oxidation, and to chemical attack by process volatiles and reactive atmospheres. Available in rod or multi-leg designs.

Silicon carbide element manufacturers typically produce a family of elements using different grades of material and different manufacturing techniques to tailor each product to a specific range of application. The effects of furnace atmosphere on SiC element (Maximum Element Temperature) MET needs to be considered in designing the furnace. The lowest METs is achieved in vacuum, both because any protective silicon dioxide layer formed by pre-oxidation will deteriorate under hard vacuum and because SiC actually vaporizes at elevated temperature under high vacuum conditions..

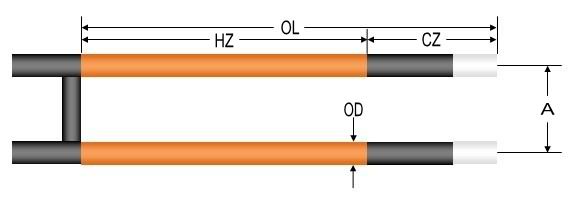

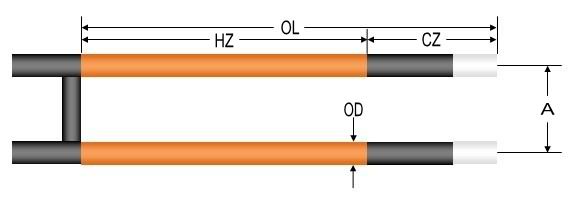

The element tubes consist of a central heating section referred to as a hot zone and two terminal sections called cold ends. The cold ends are infused with silicon metal to bring down their resistance and operating them at a lower temperature. The extreme ends of the elements are coated with aluminum contact surface with low resistance to which the electrical connections are made with braided aluminum straps. Elements are described by giving the- overall length, the heating section length, the diameter and the resistance.

All SiC heating elements oxidize (or otherwise react with the furnace atmosphere) and increase in resistance during their life in operation. Eventually, they either can no longer generate sufficient heat or they fail mechanically, and in either case they must be replaced. Traditionally, SiC heating element power supplies have been designed to supply full-rated power even if the element increases in resistance to four times the new element resistance (a 300% resistance increase). Practically speaking, such a high resistance increase is seldom reached. An allowance for a factor of two to three increases (100-200%) is usually sufficient.

Advantages:

· Available in a wide range of shapes and sizes

· Self-supporting, they can be used in furnaces that are too wide or too long to be spanned by metallic or MoSi2 heating elements

· Capable of higher operating temperatures and higher watt loadings than metallic elements

· Relatively easy to change while the furnace is hot

Disadvantages:

· More costly power control equipment than for metallic elements (multi-tap transformer required)

· Electrical resistance increases with time (aging), meaning more maintenance attention (transformer tap changing and group replacement) is required than for Metallic or MoSi2 heater

· Ceramic material risk of fracture

STA sic heating element has DB ED U W H SCR And SGR type .The resistance varies highly non-linear manner vs. temperature for all SiC elements, and the industry standard is to report this number at a temperature ~800C to 1000C.

Silicon carbide element manufacturers typically produce a family of elements using different grades of material and different manufacturing techniques to tailor each product to a specific range of application. The effects of furnace atmosphere on SiC element (Maximum Element Temperature) MET needs to be considered in designing the furnace. The lowest METs is achieved in vacuum, both because any protective silicon dioxide layer formed by pre-oxidation will deteriorate under hard vacuum and because SiC actually vaporizes at elevated temperature under high vacuum conditions..

The element tubes consist of a central heating section referred to as a hot zone and two terminal sections called cold ends. The cold ends are infused with silicon metal to bring down their resistance and operating them at a lower temperature. The extreme ends of the elements are coated with aluminum contact surface with low resistance to which the electrical connections are made with braided aluminum straps. Elements are described by giving the- overall length, the heating section length, the diameter and the resistance.

All SiC heating elements oxidize (or otherwise react with the furnace atmosphere) and increase in resistance during their life in operation. Eventually, they either can no longer generate sufficient heat or they fail mechanically, and in either case they must be replaced. Traditionally, SiC heating element power supplies have been designed to supply full-rated power even if the element increases in resistance to four times the new element resistance (a 300% resistance increase). Practically speaking, such a high resistance increase is seldom reached. An allowance for a factor of two to three increases (100-200%) is usually sufficient.

Advantages:

· Available in a wide range of shapes and sizes

· Self-supporting, they can be used in furnaces that are too wide or too long to be spanned by metallic or MoSi2 heating elements

· Capable of higher operating temperatures and higher watt loadings than metallic elements

· Relatively easy to change while the furnace is hot

Disadvantages:

· More costly power control equipment than for metallic elements (multi-tap transformer required)

· Electrical resistance increases with time (aging), meaning more maintenance attention (transformer tap changing and group replacement) is required than for Metallic or MoSi2 heater

· Ceramic material risk of fracture

STA sic heating element has DB ED U W H SCR And SGR type .The resistance varies highly non-linear manner vs. temperature for all SiC elements, and the industry standard is to report this number at a temperature ~800C to 1000C.