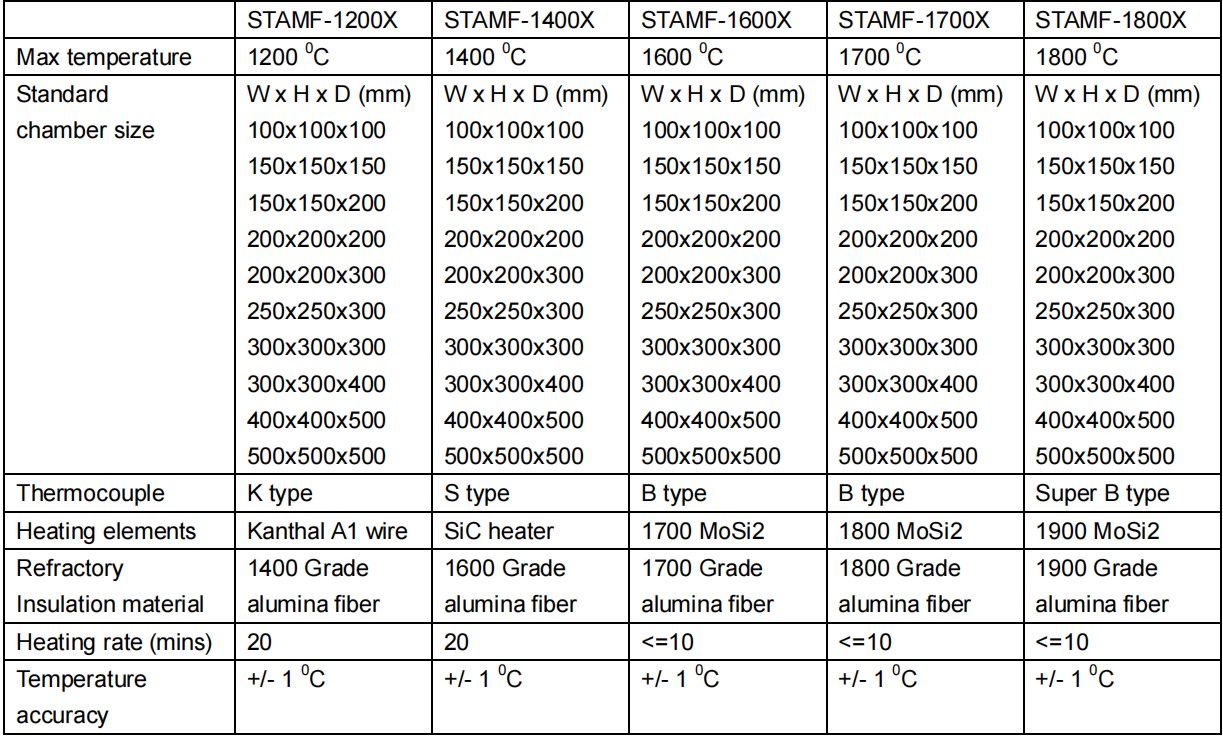

Muffle furnace is a CE certified bench-top high temperature muffle furnace. furnace The furnace consists of high quality alumina fiber insulation and heating resistance wire ,Sic heater and 1800 grade MoSi2 heating furnace elements and it's controlled by high precision SCR (Silicon Controlled Rectifier) universal power furnace controller ( updated from 2/26/13 ) and and It is an ideal tool for materials annealing furnace and sintering in your research laboratory.

Furnace Chamber | Use high temperature alumina Polycrystalline fiber chanber, energy saving and corrosion resistance(it has Light weight, fast heating rate, energy saving, time saving, high temperature resistance, corrosion resistance, good heat preservation, can meet the requirements of rapid sintering. |

Furnace structure | Double shell with fan cooling,When the electric furnace is operated at the highest temperature, the temperature outside the furnace shell is close to room temperature. |

thermocouple | B" type Pt-Rh to Pt-Rh wire Outer is purity 99.8% ceramic protection tube |

Heating element | MoSi2 heating element |

Temperature controller | 30-51 steps programmable and PID automatic control |

Temperature control accuracy | ±1℃ |

Heating Rate | 0~15℃/min(suggestion:<10.C) |

Temperature control | Over temperature protection and alarm allows for operation without attendant(s). |

related accessories | high temperature gloves,1 pair hooks,1pc Spare heater:2pcs instructions |

Warranty | Our products are warranted to be free from defects in materials or workmanship for one year from the date of purchase. Within this period, Across International will, at its sole options, replace any components that fail in normal use. |

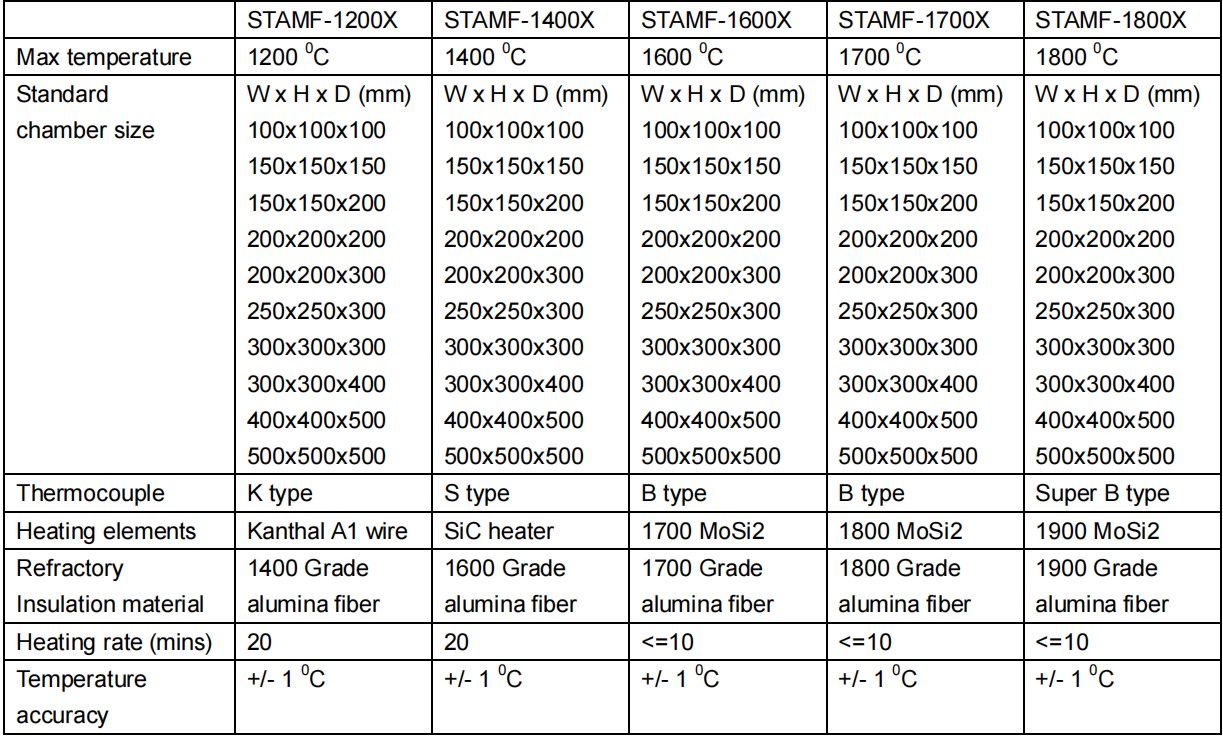

Muffle furnace is a CE certified bench-top high temperature muffle furnace. furnace The furnace consists of high quality alumina fiber insulation and heating resistance wire ,Sic heater and 1800 grade MoSi2 heating furnace elements and it's controlled by high precision SCR (Silicon Controlled Rectifier) universal power furnace controller ( updated from 2/26/13 ) and and It is an ideal tool for materials annealing furnace and sintering in your research laboratory.

Furnace Chamber | Use high temperature alumina Polycrystalline fiber chanber, energy saving and corrosion resistance(it has Light weight, fast heating rate, energy saving, time saving, high temperature resistance, corrosion resistance, good heat preservation, can meet the requirements of rapid sintering. |

Furnace structure | Double shell with fan cooling,When the electric furnace is operated at the highest temperature, the temperature outside the furnace shell is close to room temperature. |

thermocouple | B" type Pt-Rh to Pt-Rh wire Outer is purity 99.8% ceramic protection tube |

Heating element | MoSi2 heating element |

Temperature controller | 30-51 steps programmable and PID automatic control |

Temperature control accuracy | ±1℃ |

Heating Rate | 0~15℃/min(suggestion:<10.C) |

Temperature control | Over temperature protection and alarm allows for operation without attendant(s). |

related accessories | high temperature gloves,1 pair hooks,1pc Spare heater:2pcs instructions |

Warranty | Our products are warranted to be free from defects in materials or workmanship for one year from the date of purchase. Within this period, Across International will, at its sole options, replace any components that fail in normal use. |