STA low mass vacuum formed ceramic fiber heating elements are a heating element and insulation together in one complete unit. These heaters are manufactured using high quality, high purity alumina based ceramic fiber. They are offered with maximum operating temperatures of 1100°C (2012°F) or 1200°C (2192°F). STA advantages include lower operating costs, increased radiant energy, longer life, low heat loss, more energy efficient, faster heat up, greater temperature uniformity, faster recovery rates, reduced process cycle time, less maintenance, faster cool down, less installation time, and greater productivity.

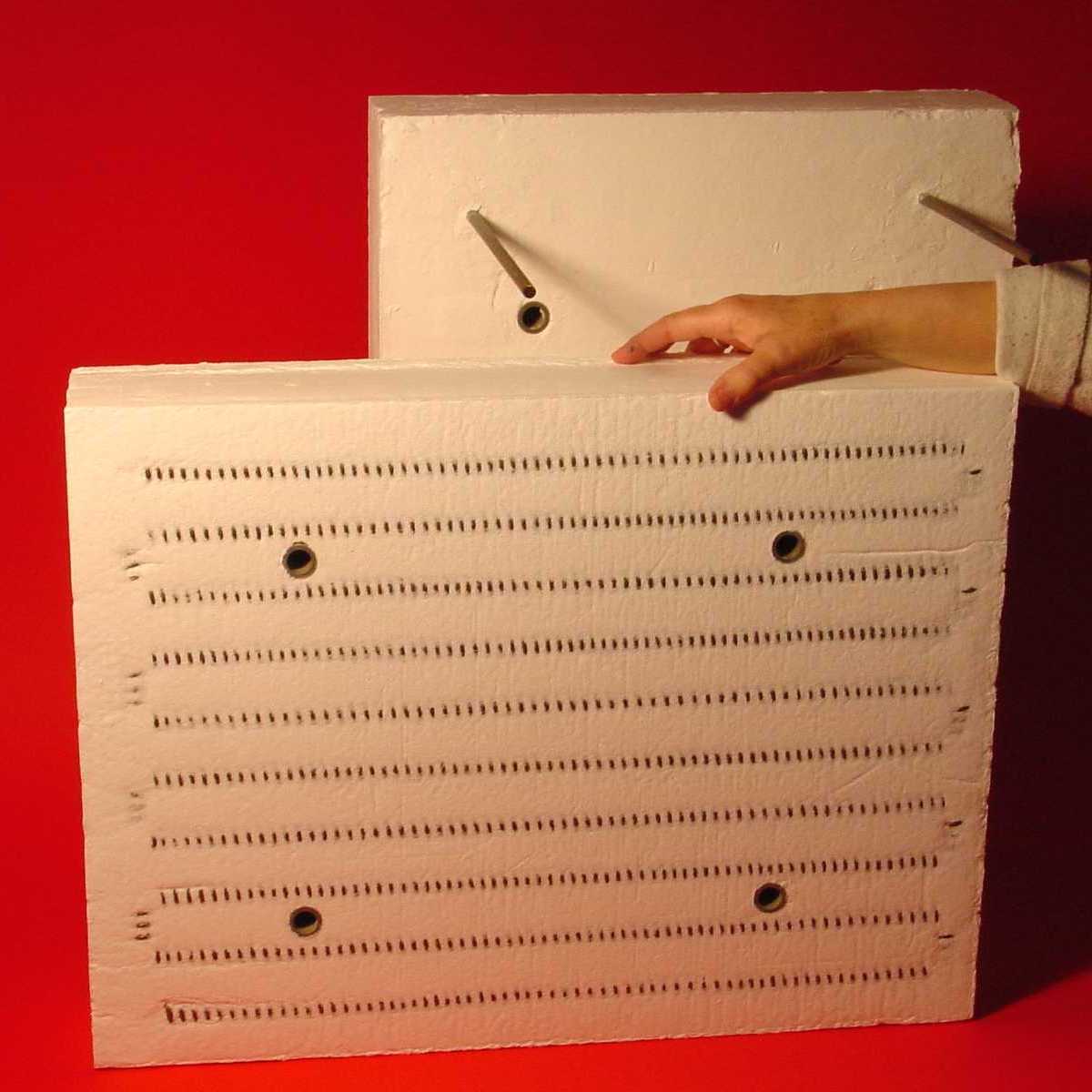

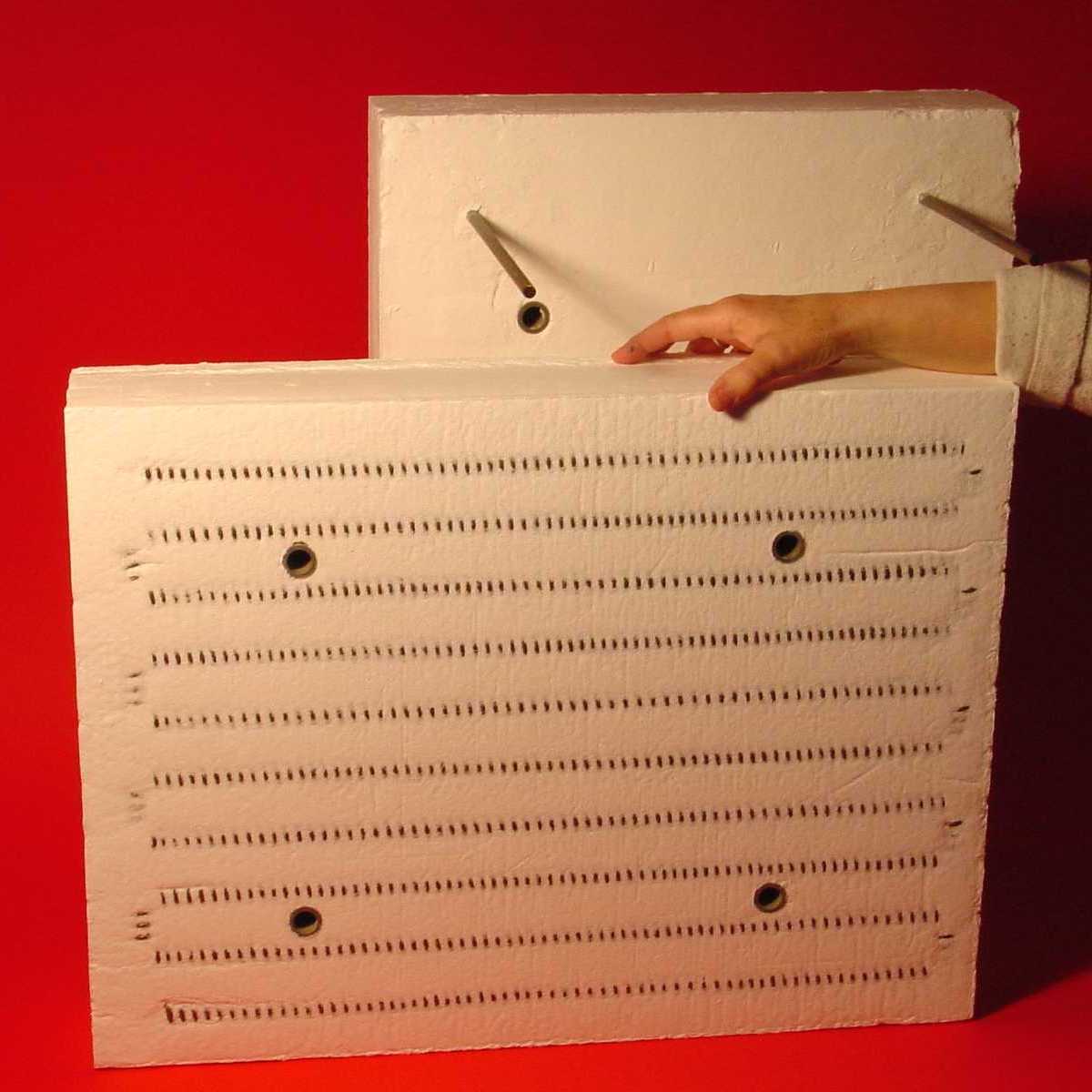

STA Ceramics’ Fiber-Insulated Heaters Type ,Finer Insulation Heaters are combinations of high quality FeCrAl resistance wire and high purity ceramic fiber thermal insulation. Fiber-Insulated Heater Type Fiber insulation heaters deliver fast, efficient and reliable uniform heat to temperatures of 1100°C (2012°F) with power densities up to 1500 watts/ft². Alumina Ceramics specializes in the design and manufacture of custom heaters for OEM furnace and thermal process equipment manufacturers as well as for end users with unique and demanding radiant heater requirements.

The lightweight ceramic fiber insulation built into FIH heaters is Alumina Ceramics’ Type which exhibits very low thermal mass, low thermal conductivity and thus can handle extremely rapid cycling. Fiber insulation heaters coiled elements are typically locked into the insulation flush with the heated surface. This provides good support for the element and ensures long heater life.

All STA Ceramics’ Fiber-Insulated Heaters are 100% organic free and will not smoke or outgas when heated.

Ceramic Fiber Heater Shapes:

· Proprietary vacuum formed, ceramic fiber insulation

· Rated up to 1100° C (1200° C optional)

· Available in round, half round, and square

· Flush, embedded, or recessed element

· 100% inorganic

· Low thermal conductivity insulation and high thermal shock resistance

· Available with thermocouple holes

· Available with black body coating

Ceramic Fiber Furnaces:

· Proprietary vacuum formed, ceramic fiber insulation

· Rated up to 1350° C

· Kanthal APM/A1 element wire

· Can be configured for line voltage operation, single or three phase

· Cylindrical, split tube, or rectangular configurations

· Alumina coating rated for 1800° C to prevent dust contamination

· Available with thermocouple holes

STA Ceramics’ Fiber-Insulated Heaters Type ,Finer Insulation Heaters are combinations of high quality FeCrAl resistance wire and high purity ceramic fiber thermal insulation. Fiber-Insulated Heater Type Fiber insulation heaters deliver fast, efficient and reliable uniform heat to temperatures of 1100°C (2012°F) with power densities up to 1500 watts/ft². Alumina Ceramics specializes in the design and manufacture of custom heaters for OEM furnace and thermal process equipment manufacturers as well as for end users with unique and demanding radiant heater requirements.

The lightweight ceramic fiber insulation built into FIH heaters is Alumina Ceramics’ Type which exhibits very low thermal mass, low thermal conductivity and thus can handle extremely rapid cycling. Fiber insulation heaters coiled elements are typically locked into the insulation flush with the heated surface. This provides good support for the element and ensures long heater life.

All STA Ceramics’ Fiber-Insulated Heaters are 100% organic free and will not smoke or outgas when heated.

Ceramic Fiber Heater Shapes:

· Proprietary vacuum formed, ceramic fiber insulation

· Rated up to 1100° C (1200° C optional)

· Available in round, half round, and square

· Flush, embedded, or recessed element

· 100% inorganic

· Low thermal conductivity insulation and high thermal shock resistance

· Available with thermocouple holes

· Available with black body coating

Ceramic Fiber Furnaces:

· Proprietary vacuum formed, ceramic fiber insulation

· Rated up to 1350° C

· Kanthal APM/A1 element wire

· Can be configured for line voltage operation, single or three phase

· Cylindrical, split tube, or rectangular configurations

· Alumina coating rated for 1800° C to prevent dust contamination

· Available with thermocouple holes